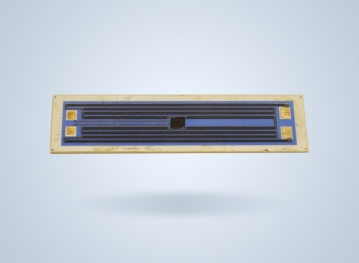

Fault detection and repair of heating chip

The heating plate is applied to the industrial sectors baking, drying, and constant temperature heating the sample for other temperature test, is genetic, biological, pharmaceutical and health care, environmental protection, biochemical laboratory, analysis room, teaching and research of essential tools. The possibility of any equipment malfunction, in order to make the electric heating plate better work, reduce the number of failure, increase the work efficiency, here the typical fault are analyzed in detail, introduces the process, summed up the thinking of maintenance.

Fault 1: turn on the heating switch of the thermostatic heating platform, and the aluminum platform will not be heated:

Reasons: 1. The possibility of damage of heating pipe is great; 2. The heating switch is broken; 3. Bad solid relay; The thermostat is broken.

Test and maintenance methods:

Open the bottom cover of the thermostatic platform:

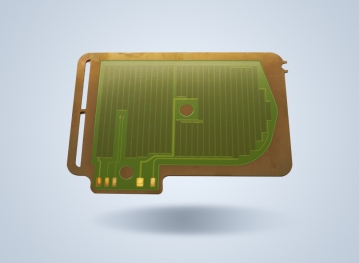

Detection of heat pipe: first cut off the power supply of the whole machine and use the multimeter to test the resistance of the heat pipe at ohm. The wire of the heat pipe is connected together and should be cut off for detection. If the resistance is infinite or several ohms are visible, the plate thick film heater is damaged and replaced.

2. Check the heating switch: also, cut off the entire power supply of the machine first, play the multimeter to the buzzer file, put the switch to one word file, measure whether the switch terminal is in the state of connection with the meter pen, and both terminals are connected to explain that the switch is good, otherwise it needs to be replaced.

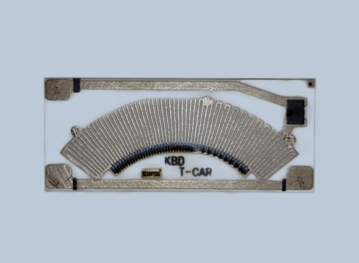

3. Detect solid-state relays: connect the constant temperature platform with power supply, but be careful of electric shock! Then turn on the heating switch to see if the indicator light of the solid-state relay is on or shining. If it is not on, check the 3-4 terminals of the solid-state relay with a multimeter to see if there is a voltage of 12VDC. If not, the thermostat is damaged. Then put the multimeter to the gear of 750VAC and measure the 1-2 ends of the solid relay with the meter pen. If there is a voltage of 220VAC and no change, the solid relay can be damaged and replaced.

4. Check the temperature controller: connect the power to the thermostat and turn on the heating switch to see if the thermostat is normally displayed. If it is normally displayed as usual, dial the multimeter to the dc 20VDC.

Fault 2: high and low temperature of aluminum platform:

One of the heating pipes has been damaged, and the heating pipes are measured according to the test above.

Fault 3: the number of thermostat jumps randomly:

1. If the number code of the SV window has the "AT" letter in the jump, it means that the wrong length of the decimal point shift key was pressed during the operation, and the thermostat was started to adjust. To cancel, please keep pressing the decimal point shift key for 3 seconds and then release.

2. If the digital tube of PV window shows 1312 and the digital tube of SV window shows "ORAL", then the temperature line is opened and replaced.