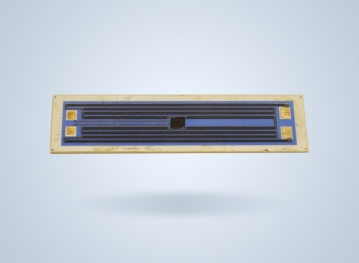

Is it safe to use a metal heating chip?

Is it safe to heat the upper sheet with metal? This is a question frequently asked by most people who use this product. As the thin heating plate is a new non-standard product, not many people know about it. The following is the author's brief explanation that the metal heating plate is safe to use:

First of all, the heating film heating plate is planned in accordance with the electrical and electrical specifications, and there is a certain creepage interval whether in the heating wire or in the connection part.

Secondly, heating chip used insulating material, whether it's PET, is still the polyimide or silicone rubber, mica, have very good insulation effect, the electric strength test: 1500 v / 1 min5ma, no breakdown flashover, insulation resistance: 5 m Ω or higher. Therefore, there is no leakage phenomenon;

Third, different environment and different temperatures choose different insulation materials. When the customer orders, relevant personnel of our company will make certain evaluation according to the temperature requested by the customer, and then introduce appropriate electric heating film.

Fourthly, the insulation materials used in the production of heating sheets are made through high temperature and high pressure, which ensures that there will be no exposure of heating wires within the specified temperature range.

Fifth, in the planning of the heating plate, our company will plan the power according to the temperature. The heating wire of the product will adjust its power according to the temperature.

Through the above analysis, the heating plate is safe to use, and its surface heating, uniform temperature characteristics will be increasingly exposed to many planners and users

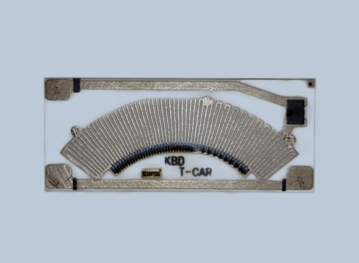

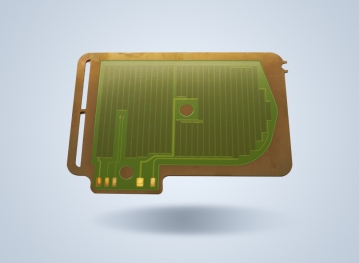

The silicon rubber heating plate adopts the heating core technology, which can fundamentally deal with the following questions:

1. The heating plate is uniformly heated, which cannot be achieved by the common heating wire. The common heating wire is manually placed in the silicon rubber electric heating belt, and the width and width of the wire are inconsistent.

2. The heating plate has stable power and fast temperature rise. The silicon rubber heating plate using the heating plate has features of fast temperature rise and high thermal transformation.

3. The silicon rubber heating plate adopts metal heating plate, which can greatly increase the unit power density, up to 2W/ cm2.

The heating plate has the advantages above, but there are also some defects in the practical application, as follows:

1. The silicon rubber heating plate is relatively long in practice, but the heating plate is more or less restrained in length.

2. The width of the heating plate determines the width of the silicon rubber heating plate, and the conventional heating plate is tens of centimeters wide.

3. From the beginning of the planning, the heating plate has higher requirements than the artificial silk method, and each process is more rigorous;

4. Using the silicon rubber heating plate of the heating plate, the unit square meter price is higher than the cost of human cloth;

The address of this article:http://www.qiluyoubeng.com/en/news/406.html

Key word:

The next one:Fault detection and repair of heating chip