The heating base of metal is more stable

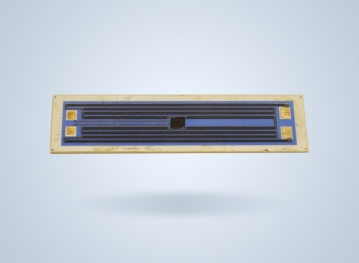

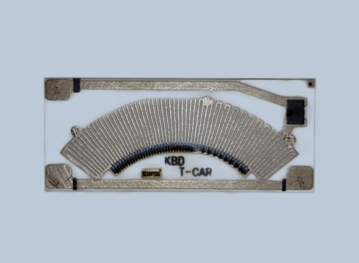

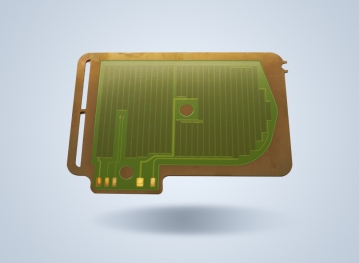

There are many kinds of electric heating films. We have introduced them before, and we will not list them here. Our company produces various kinds of electric heating films mainly with metal as heating base material, among which the representative ones are four series of polyimides, PET, mica and silicon rubber.

Taking metal as the heating base material can effectively improve the power stability of the electric heating film, and at the same time, it is also much more important than other materials in terms of thermal transformation. However, the metal heating wire is designed through computer aided design with minimal tolerance, so the temperature difference on the same electric heating film can be basically ignored. Thick film heaters on metal base have many advantages over traditional heaters

1. Service life

The embedded heating makes the metal heating wire inside the electric heating film not oxidized, and there is no open fire at work, so as to effectively improve the service life of the electric heating film.

2. Safety in use

All the heating filaments produced by our company are encapsulated in highly insulating materials. Moreover, they are specially treated at the wiring position of the power supply line to avoid leakage of electricity. At the same time, we have passed various performance tests when leaving the factory.

Stability of thick film heater

3. Good electrical contact performance

Electric contact performance of the electric products is a key product performance evaluation indicators, metal electrothermal film conductive heating element for the metal film, the electrothermal current-carrying article is thickening metal strip, can carry large current, because the metal electrothermal film conductive heating element and thickening of the current-carrying article all for the same metal, small contact resistance, the contact area is large, there is a point contact, metal substrate with article current-carrying potential, electric performance is good, no poor contact, fever, discharge phenomenon, long running without quality problem

4. Self-limiting temperature (PTC) characteristics

Well-known metal itself to have the limit temperature characteristics, namely when the temperature resistance increases, itself in power decrease, restricted temperature rise, ring da card electrothermal film on the metal original features and metal ions doped high positive temperature coefficient, greatly improving the limit temperature characteristics, metal electrothermal film since the limit temperature characteristics in metal electrothermal film temperature heat up faster than ink electrothermal film, the temperature reaches the design value, the power decrease, the current decline. This is because the low temperature metal thermal film power, fast heating, high temperature, power decline.